Enhancing Safety and Uptime in High-Density Data Centers with the Starline Remote Plug-In Actuator

As artificial intelligence (AI), high-performance computing (HPC), and digital services continue to drive exponential data growth, data centers are evolving at unprecedented speed. Today’s facilities face more pressure than ever to deliver reliable power in increasingly dense environments, all while adhering to stringent safety standards and minimizing downtime.

Power densities have surged—rising from just 4–5 kW per rack a decade ago to upwards of 50 kW today. These next-generation workloads are pushing the limits of traditional power distribution systems, and the stakes are higher than ever. Operators must navigate complex requirements: ensuring uptime, protecting personnel, and enabling efficient operations in live environments. In this landscape, every second of downtime is costly, and any safety compromise carries a significant risk.

To address these challenges head-on, a new innovative solution has been designed to offer a safer alternative for connecting equipment to a live power busway: the Starline Remote Plug-In Actuator.

A New Era of Safety and Efficiency in Live Power Environments

Built upon the robust and reliable Starline Track Busway technology, the Remote Plug-In Actuator represents a significant leap forward in how data centers manage power distribution. Facility managers have long valued the convenience and safety of Starline’s Track Busway plug-in units, which feature a manual twist-and-lock process to ensure proper electrical grounding and mechanical connection. With the Remote Plug-In Actuator, Starline takes this innovation a step further, allowing operators to engage and disengage plug-in units remotely.

The Remote Plug-In Actuator enables plug-in units to be activated via fiber optic cable or secure Bluetooth connectivity from up to 10 meters away. This crucial advancement means data center personnel can complete installations or perform maintenance without physically entering the incident energy zone, significantly reducing the risk of arc flash or other electrical hazards.

Designed for Today’s Demands: High-Density, High-Risk, and Always-On

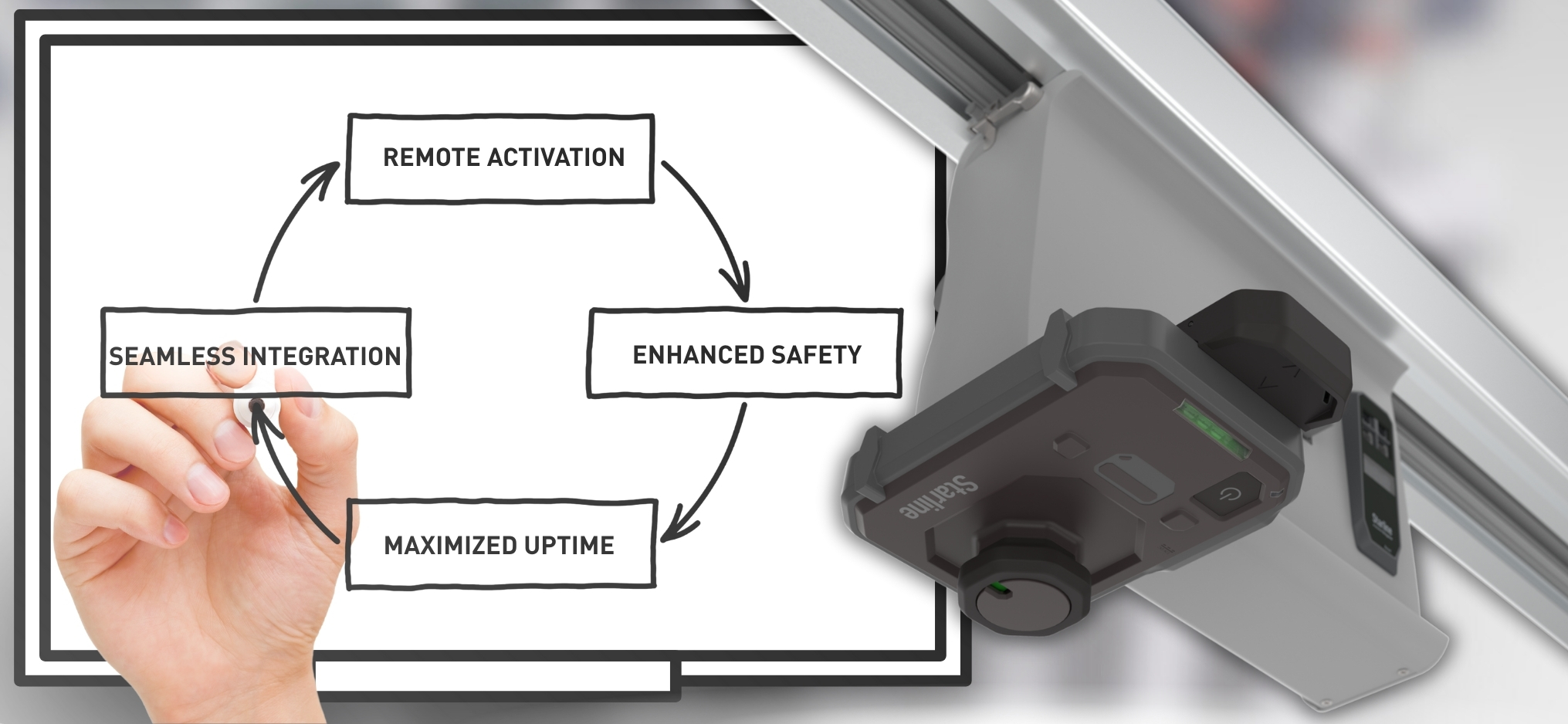

AI and HPC deployments are redefining what it means to be a “high-density” facility. These environments are power-hungry and often unpredictable, requiring a level of operational agility and safety that conventional systems were not designed to handle. In these settings, the Remote Plug-In Actuator offers several critical benefits:

1. Remote Activation

By eliminating the need to manually engage plug-in units directly on the busway, the actuator allows technicians to operate from a safe distance—well outside any arc flash boundary. Whether through fiber optics or encrypted Bluetooth, remote control means less time spent near energized components and more confidence in every move.

2. Enhanced Safety

Working within live power environments has traditionally posed risks, especially during installation or maintenance tasks. The actuator minimizes these risks by removing the need for physical interaction with live components.

3. Maximized Uptime

One of the biggest challenges for data center managers is balancing uptime with necessary system changes. Because the actuator supports plug-in unit installation while the busway remains live, there’s no need to schedule downtime for unit replacement or upgrades. Operations continue uninterrupted—even during hardware modifications.

4. Seamless Integration

Compatibility is essential in fast-paced environments. The actuator is fully integrated with the existing Starline Track Busway architecture, allowing facilities to adopt this innovation without retrofitting or replacing infrastructure. It’s a plug-and-play enhancement that modernizes power delivery systems instantly.

Empowering Safer AI and HPC Deployments

As AI adoption accelerates, data centers must adapt quickly. High-wattage racks, accelerated GPU workloads, and the dynamic nature of AI models all demand scalable and resilient infrastructure. Yet even as power demands increase, facility managers cannot compromise on safety or uptime.

The Starline Remote Plug-In Actuator directly addresses this industry-wide dilemma. Its ability to remotely engage power connections means operators can:

Minimize the number of people exposed to energized components.

Perform critical changes without impacting live workloads.

Accelerate deployment times without introducing unnecessary risk.

This is particularly relevant in hyperscale and colocation environments, where client expectations around uptime and safety are uncompromising. The actuator gives these facilities the tools they need to scale confidently while safeguarding operations and personnel.

Innovation of Power Distribution to Meet Safety Challenges

Legrand has long been at the forefront of data center innovation, and the Starline brand has become synonymous with reliability, modularity, and performance. The Remote Plug-In Actuator is the latest evolution in this legacy—a response to the changing needs of data centers operating in an always-on, increasingly digital world.

Mathew George, European Vice President of Critical Power & Key Accounts at Legrand, summarized it well: “With the launch of the Remote Plug-In Actuator, we are enhancing operator safety by enabling remote engagement, increasing operational flexibility, and providing greater protection in AI and HPC environments.”

By combining patented safety mechanisms with intuitive remote technology, Legrand delivers a future-ready solution that streamlines operations, enhances compliance, and keeps people safe.

The Bottom Line: Smarter Power Distribution Starts Here

The rapid growth of AI and high-density computing has redefined the demands on data center operations. Safety, uptime, and scalability aren’t optional in this high-stakes environment—they’re essential. The Starline Remote Plug-In Actuator equips operators with the tools to meet these challenges head-on, safely, and efficiently.

Canada

Canada

Latin America (English)

Latin America (English)

Latin America (Espanol)

Latin America (Espanol)

USA

USA

China

China

India

India

Japan

Japan

Republic of Korea

Republic of Korea

South East Asia (English)

South East Asia (English)

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Netherlands

Netherlands

Spain

Spain

Switzerland

Switzerland

Turkey

Turkey

UK

UK

Africa (english)

Africa (english)

Africa (français)

Africa (français)

Middle East (english)

Middle East (english)

Australia

Australia

New Zealand

New Zealand