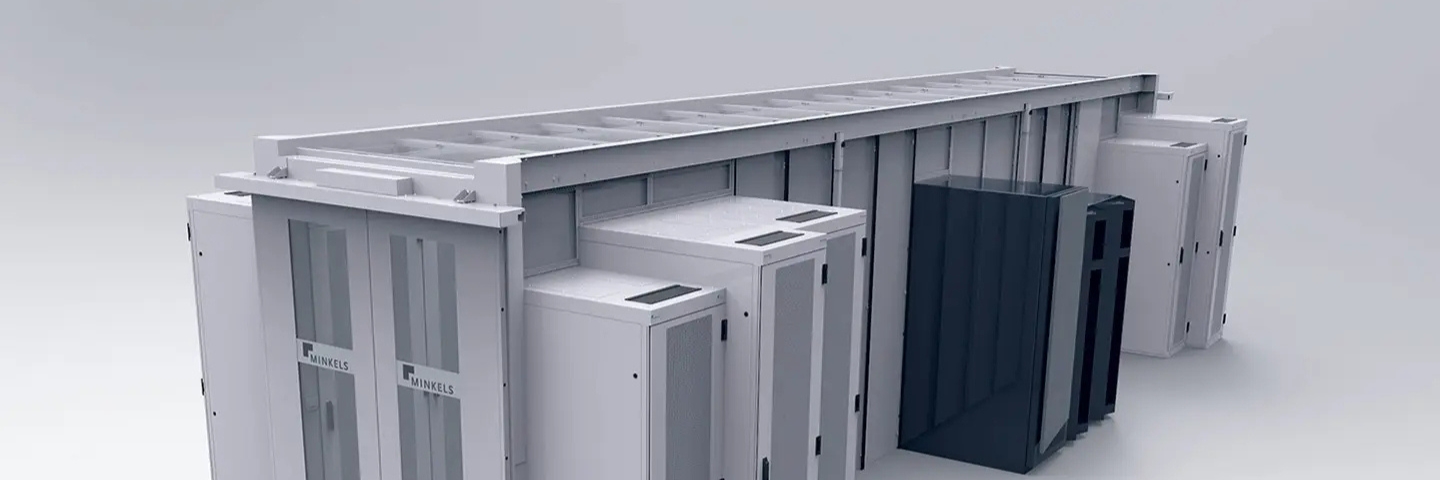

Rear-Door Heat Exchangers (RDHx): Smart Cooling at the Rack Level

Rear-Door Heat Exchangers (RDHx) deliver targeted cooling by replacing standard server cabinet doors with integrated heat exchange units. These systems intercept hot exhaust air directly at the source, supporting rack densities from 15 kW to 200+ kW while maintaining compatibility with existing air-cooled IT equipment.

What Is a Rear-Door Heat Exchanger?

A Rear-Door Heat Exchanger is a rack-mounted cooling solution that replaces the traditional rear door of a server cabinet with an active heat removal system. By positioning the heat exchanger directly in the path of server exhaust air, RDHx units capture and cool hot air before it enters the data center environment, dramatically reducing room-level cooling requirements.

How RDHx Systems Work

Heat removal process:

- Hot air capture - Server exhaust flows directly into the heat exchanger

- Heat transfer - Chilled water circulating through coils absorbs thermal energy

- Cool air discharge - Cooled air returns to the room at near-ambient temperature

- Continuous operation - Process repeats automatically based on thermal load

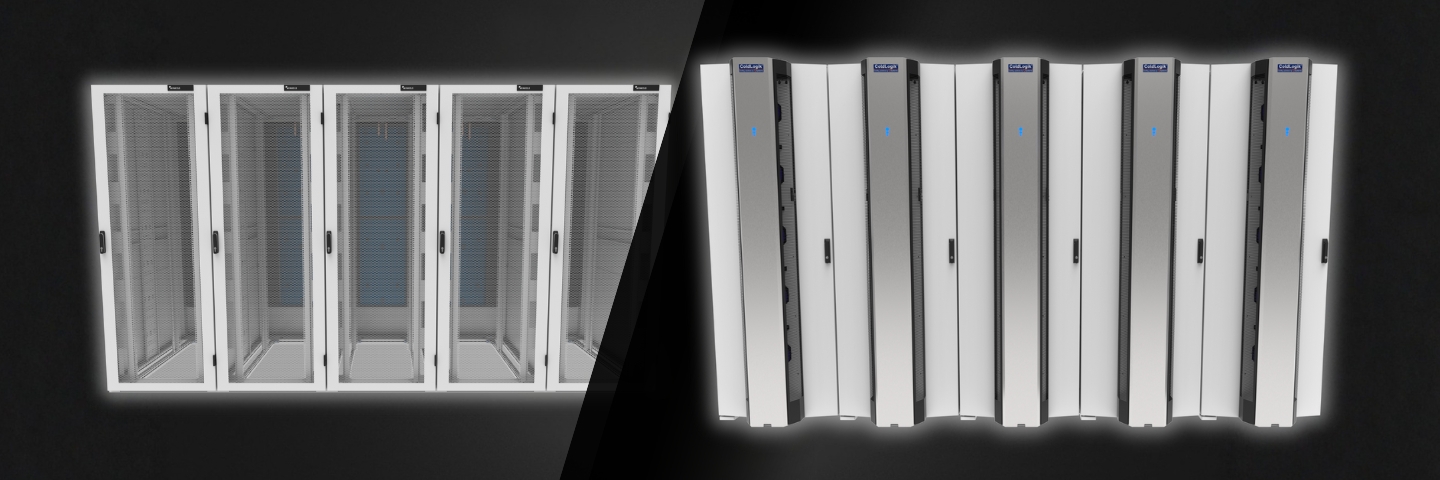

Passive vs. Active RDHx Systems

| System Type | Power Range | Fan Operation | Best Applications |

|---|---|---|---|

| Passive RDHx | Up to 20 kW | Relies on server fans | Moderate density, energy-conscious deployments |

| Active RDHx | 15-200+ kW | Independent EC fans with variable speed | High-density AI, HPC, GPU workloads |

Why Choose Rear-Door Heat Exchangers?

Traditional perimeter cooling struggles with today's high-density computing demands, creating hot spots and inefficient airflow patterns. RDHx systems address these challenges by implementing cooling directly at the heat source, providing a bridge between conventional air cooling and full liquid cooling infrastructure while supporting dramatically higher power densities.

Modern Computing Challenges

- Rising rack densities - AI and HPC workloads pushing 50+ kW per rack

- Thermal hot spots - Concentrated heat generation overwhelming room cooling

- Energy efficiency demands - Need for improved PUE and sustainability

- Infrastructure constraints - Limited space for traditional cooling expansion

Key Benefits of RDHx Technology

Rear-door heat exchangers provide measurable improvements in cooling capacity, energy efficiency, and operational flexibility while maintaining compatibility with existing data center infrastructure. These systems offer unique advantages for high-density computing environments where traditional cooling methods reach their limits.

1. Exceptional Cooling Capacity

- High-density support - Active units handle 15-200+ kW per rack

- Scalable performance - Cooling capacity matches IT load requirements

- AI/HPC ready - Supports GPU-intensive and machine learning workloads

- Future-proof design - Accommodates increasing power densities

2. Retrofit Compatibility

- Existing infrastructure - Works with current server cabinets and IT equipment

- Minimal disruption - Installation without data center redesign

- Preserve investments - Extends life of air-cooled servers and infrastructure

- Gradual deployment - Implement rack-by-rack as needed

3. Space and Energy Efficiency

- Zero floor space - Replaces existing door, adds no footprint

- Reduced room cooling - Eliminates need for additional CRAC/CRAH units

- Improved PUE - Significantly reduces overall facility energy consumption

- Variable operation - Active units adjust fan speed based on actual load

Technical Configurations and Performance

RDHx systems are engineered for different performance requirements and deployment scenarios. Understanding the technical specifications and operational characteristics helps determine the optimal configuration for specific rack densities and cooling requirements.

Passive RDHx Systems

Optimal for: Moderate density racks with reliable server airflow

Technical specifications:

- Power capacity: Up to 20 kW per rack

- Fan operation: Server-dependent airflow

- Energy consumption: Zero

- Noise level: Minimal operational noise

- Maintenance: Simple, passive operation

Active RDHx Systems

Optimal for: High-density and variable load environments

Technical specifications:

- Power capacity: 15-200+ kW per rack

- Fan operation: Independent EC fans with variable speed control

- Energy consumption: Optimized fan power based on thermal load

- Control integration: Smart sensors and automated operation

- Scalability: Dynamic response to changing conditions

Chilled Water Integration

- Supply temperature: Typically 14-28°C

- Flow rates: Variable based on thermal load

- Pressure requirements: Standard chilled water system compatibility

- Quick disconnects: Tool-free connections for maintenance

- Leak detection: Integrated sensors and containment options

Installation and Design Considerations

Successful RDHx deployment requires careful planning around infrastructure integration, space allocation, and operational requirements. These considerations ensure optimal performance while maintaining accessibility and safety standards throughout the installation lifecycle.

Infrastructure Requirements

| Component | Passive RDHx | Active RDHx |

|---|---|---|

| Chilled Water | Required - standard loop | Required - standard loop |

| Electrical Power | None | 120/240V for fans and controls |

| Control Integration | Optional | Recommended for optimization |

| Maintenance Access | Rear access required | Front and rear access |

Space and Access Planning

- Rack depth - Additional 15-30cm for heat exchanger unit

- Aisle spacing - Ensure adequate rear access for maintenance

- Containment compatibility - Works with hot/cold aisle containment

- Service clearance - Plan for water connections and control access

Installation Best Practices

- Water routing - Design piping runs to minimize leak risk

- Quick disconnects - Use reliable, tool-free connections

- Leak detection - Install sensors at connection points

- Control integration - Connect to facility monitoring systems

Performance Optimization and Maintenance

Maximizing RDHx effectiveness requires attention to system tuning, preventive maintenance, and performance monitoring. These practices ensure consistent cooling performance while minimizing energy consumption and operational disruption.

Maintenance Requirements

- Monthly: Visual inspection, connection checks, performance monitoring

- Annually: Complete system inspection, leak testing, performance validation, Coil cleaning

Performance Monitoring

- Thermal effectiveness - Track inlet/outlet temperature differentials

- Energy efficiency - Monitor fan power consumption and cooling capacity

- Water consumption - Optimize flow rates for efficiency

- System integration - Verify coordination with facility systems

Best Use Cases and Applications

RDHx technology excels in specific deployment scenarios where high cooling capacity, retrofit compatibility, and space efficiency are critical requirements. Understanding these applications helps identify when rear-door heat exchangers provide the greatest operational and economic value.

Ideal Applications

AI and Machine Learning Environments

- High-density GPU clusters requiring 50+ kW cooling

- Variable workloads with dynamic thermal requirements

- Need for precise temperature control and reliability

High-Performance Computing (HPC)

- Compute clusters with concentrated heat generation

- Research facilities with evolving cooling requirements

- Environments requiring maximum uptime and performance

Colocation and Multi-Tenant Facilities

- Mixed tenant requirements and varying power densities

- Need for flexible, scalable cooling solutions

- Space-constrained environments with premium real estate costs

Retrofit and Upgrade Projects

- Existing facilities requiring increased cooling capacity

- Infrastructure with limited space for traditional cooling expansion

- Gradual modernization of legacy data center environments

Implementation Planning and ROI

Deploying RDHx systems requires strategic planning around infrastructure readiness, implementation timeline, and financial justification. Understanding these factors ensures successful deployment while maximizing return on investment and operational benefits.

Infrastructure Assessment

- Chilled water capacity - Verify adequate cooling plant capacity

- Electrical requirements - Plan power distribution for active units

- Space evaluation - Confirm aisle spacing and access requirements

- Integration planning - Design control and monitoring connections

Financial Considerations

- Capital costs - RDHx units, installation, and infrastructure upgrades

- Operating savings - Reduced room cooling, improved efficiency

- Avoided costs - Elimination of additional CRAC/CRAH units

- Scalability value - Future-proofing for density increases

Legrand Data Center Cooling Solutions

Implementing advanced cooling technologies requires the right infrastructure support and expertise. Legrand provides comprehensive solutions for modern data center thermal management, from power distribution and monitoring to physical infrastructure that enables optimal cooling performance.

Explore Legrand's cooling infrastructure solutions:

- Rear-Door Cooling Solutions - Complete infrastructure support for RDHx implementations, including power distribution, monitoring, and control systems designed for rack-level cooling technologies.

- Row-Based Cooling Infrastructure - Integrated solutions supporting in-row cooling deployments, featuring optimized power delivery, environmental monitoring, and cable management systems.

Our data center specialists can help you design and implement the infrastructure foundation that enables successful cooling technology deployment while ensuring reliability, efficiency, and scalability for your facility's evolving needs.

Conclusion

Rear-Door Heat Exchangers represent a strategic evolution in data center cooling, combining the reliability of air cooling with the efficiency of liquid cooling at the rack level. This technology bridges the gap between traditional cooling methods and advanced liquid cooling infrastructure, providing immediate benefits while enabling future scalability.

For data centers facing increasing power densities, space constraints, or energy efficiency requirements, RDHx systems offer a proven path to enhanced thermal management. The technology's retrofit compatibility makes it particularly valuable for existing facilities, while its scalability ensures long-term viability as computing demands continue to grow.

As AI, HPC, and high-density computing become standard rather than exceptional, rear-door heat exchangers provide the cooling foundation necessary to support these demanding workloads while maintaining operational simplicity and cost-effectiveness.

Canada

Canada

Latin America (English)

Latin America (English)

Latin America (Espanol)

Latin America (Espanol)

USA

USA

China

China

India

India

Japan

Japan

Republic of Korea

Republic of Korea

South East Asia (English)

South East Asia (English)

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Netherlands

Netherlands

Spain

Spain

Switzerland

Switzerland

Turkey

Turkey

UK

UK

Africa (english)

Africa (english)

Africa (français)

Africa (français)

Middle East (english)

Middle East (english)

Australia

Australia

New Zealand

New Zealand