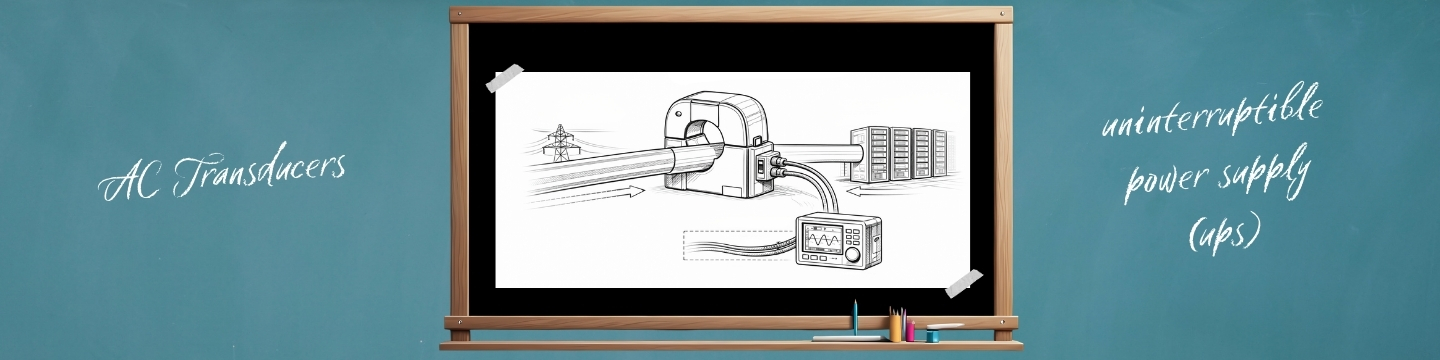

Precision AC Transducers for Real-Time Power Monitoring in Data Centers

Precision alternating current transducers provide the critical measurement accuracy needed for real-time power monitoring in UPS-protected data center environments. These specialized sensor devices convert AC electrical currents into proportional signals that enable UPS controllers to maintain optimal power quality and maximize uptime for mission-critical IT infrastructure.

How AC Current Transducers Enable UPS Power Quality Control

An alternating current transducer functions as the measuring interface between high-power electrical circuits and sensitive control electronics. The device monitors load currents flowing through UPS systems and generates isolated output signals that accurately represent the power conditions. This proportional output allows UPS control systems to make rapid adjustments based on actual electrical demand, maintaining stable power delivery to connected equipment while providing galvanic isolation that protects sensitive electronics from high voltages.

Hall Effect and Coil-Based Sensor Technologies

Two primary sensor technologies deliver the accuracy and reliability required for data center applications:

Hall Effect Transducers

Hall Effect Transducers employ semiconductor-based sensors that detect magnetic fields generated by current flow. When AC current passes through a conductor, the resulting magnetic field induces a voltage across the Hall sensor element. This technology offers several advantages for UPS applications:

- Non-contact measuring with no insertion losses in the primary circuit

- Wide bandwidth capability for fast transient response

- Stable operation across temperature variations

- Capability to measure both AC and DC components

Coil-Based Transducers

Coil-Based Transducers utilize electromagnetic induction principles, where the alternating current creates a magnetic field that induces a proportional signal in a secondary coil winding. These transducers provide excellent accuracy for standard AC power measurement applications and offer simple, robust construction.

RMS Accuracy and Signal Processing Features

True RMS measuring capability ensures transducers accurately capture the actual heating effect of complex AC waveforms containing harmonics and distortion. Data center power systems often experience non-sinusoidal loads from switch-mode power supplies, making RMS measurement essential for proper load management.

Key specifications include primary current ranges from a few amps to several hundred amps, standard outputs of 4-20mA current loops or 0-5V/0-10V voltage signals, RMS accuracy typically better than 1% across the measuring range, and frequency response from 50/60 Hz up to several kHz for capturing harmonics.

Isolation and Noise Immunity for Reliable Operation

Electrical isolation between inputs and outputs provides critical protection and noise immunity. The isolation barrier, typically rated for several thousand volts, prevents ground loops and eliminates common-mode interference that could degrade measurement accuracy. This feature proves particularly valuable in data centers where multiple grounding points and electromagnetic interference from IT equipment can compromise signal integrity.

The isolated secondary output remains unaffected by voltage transients and electrical noise present on the primary power circuit. This ensures the UPS controller receives clean, reliable signals for accurate power monitoring and control decisions.

Temperature Stability for Data Center Environments

Data center operating conditions demand transducers that maintain accuracy across wide temperature variations. Quality units incorporate temperature compensation circuits that automatically adjust for thermal drift, typically operating from -10°C to +65°C with temperature coefficients better than ±0.1% per degree Celsius. The minimal drift ensures consistent accuracy in both climate-controlled equipment rooms and warmer electrical enclosures.

Mounting Options and Installation Flexibility

Modern transducers offer flexible mounting configurations to accommodate various UPS panel layouts:

DIN Rail Mounting

DIN Rail Mounting provides the standard installation method for electrical panels and distribution equipment. The transducer snaps securely onto standard 35mm DIN rail, allowing easy installation and removal for service. DIN rail mounting positions the device conveniently within control panels alongside other monitoring and protection equipment.

Panel Mounting

Panel Mounting options accommodate direct installation through enclosure walls or mounting plates. Screw terminals or bolt-down configurations provide secure mechanical attachment. Some units feature compact, narrow profile designs that minimize space requirements in densely packed electrical panels.

Split-Core Designs

Split-Core Designs enable installation around existing cable runs without circuit interruption, offering significant advantages during system upgrades or modifications.

Integration with UPS Control Systems

Transducers deliver their output signals through standard electrical connections suitable for direct integration with UPS controllers and monitoring systems:

- Analog Outputs: Voltage and current signal types connect directly to controller analog inputs

- Digital Communication: Advanced models may incorporate RS-485 or Modbus protocols for networked monitoring

- Auxiliary Power Supply: Most transducers require auxiliary power for the signal conditioning electronics, typically 24 VDC or universal 85-265 VAC supply range

- Configuration Features: Some units include DIP switch settings for adjusting output range, enabling easy field configuration without external tools

The standardized signals interface seamlessly with programmable logic controllers, SCADA systems, and dedicated UPS management platforms.

Application Benefits for Data Center Operations

Implementing precision current transducers in UPS systems delivers measurable operational benefits:

- Enhanced Uptime: Accurate real-time load monitoring enables proactive capacity management and prevents overload conditions that could trigger system shutdowns.

- Power Quality Optimization: Continuous current measurement provides the feedback necessary for UPS systems to maintain tight voltage regulation and minimize harmonic distortion.

- Energy Management: Detailed current data supports energy usage analysis and efficiency optimization efforts, helping data centers reduce operational costs.

- Predictive Maintenance: Long-term trending of current patterns can reveal developing issues before they cause failures, allowing scheduled maintenance rather than emergency repairs.

- Redundancy Verification: In redundant UPS configurations, individual current measurement on each unit ensures proper load sharing and identifies imbalanced conditions.

Selection Criteria for Data Center Applications

Choosing the appropriate transducer requires evaluating several technical factors. Select a current transducer rated for at least 120% of maximum expected load current to provide measurement headroom. Data center applications typically require 0.5% to 1% accuracy class units for reliable power monitoring. Choose current loop outputs for long cable runs with superior noise immunity, or voltage outputs for shorter distances. Verify transducers meet relevant safety standards and ensure temperature specifications match the installation environment.

The combination of precision measurement, robust isolation, and flexible mounting makes AC current transducers indispensable components in modern UPS-protected data center infrastructure. These sensor devices form the foundation for intelligent power management systems that keep critical IT operations running reliably and efficiently.

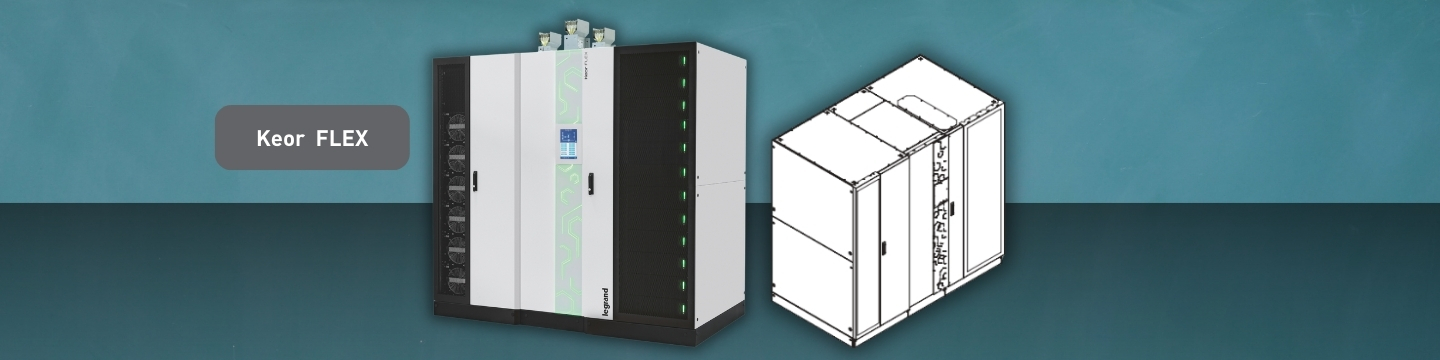

Partner with Legrand for Data Center Power Solutions

Legrand integrates precision AC current transducers into comprehensive UPS systems engineered for mission-critical data center applications. Our modular UPS platforms, including the advanced Keor FLEX high-power modular system with up to 98.4% efficiency and scalability from 100kW to 4.8MW, incorporate precision monitoring technology alongside multiple battery technology options including VRLA and lithium-ion to deliver complete power protection solutions.

Contact our data center specialists today to discuss how Legrand UPS systems can protect your critical infrastructure.

Canada

Canada

Latin America (English)

Latin America (English)

Latin America (Espanol)

Latin America (Espanol)

USA

USA

China

China

India

India

Japan

Japan

Republic of Korea

Republic of Korea

South East Asia (English)

South East Asia (English)

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Netherlands

Netherlands

Spain

Spain

Switzerland

Switzerland

Turkey

Turkey

UK

UK

Africa (english)

Africa (english)

Africa (français)

Africa (français)

Middle East (english)

Middle East (english)

Australia

Australia

New Zealand

New Zealand