Integrated Electrical Ecosystems for Safe and Reliable Power Distribution

Data centers demand electrical equipment and infrastructure that delivers absolute reliability whilst simplifying design, installation, and maintenance. Fragmented systems from multiple vendors create integration challenges, compatibility issues, and coordination gaps that compromise uptime. Legrand's integrated electrical ecosystem addresses these challenges through comprehensive solutions spanning UPS systems, power distribution, protection devices, and monitoring platforms - all engineered to work cohesively whilst meeting stringent safety standards.

The Cohesive Ecosystem Advantage

Data center electrical infrastructure typically involves dozens of component types from rectifiers and switchgear to distribution panels and monitoring systems. When sourced from disparate vendors, these components require extensive integration engineering, custom interface development, and ongoing coordination between multiple support teams.

Legrand's ecosystem approach delivers pre-engineered compatibility across the entire power chain. UPS outputs interface seamlessly with distribution equipment. Protection devices coordinate properly with upstream and downstream components. Monitoring systems provide unified visibility across all infrastructure elements through common protocols.

This integration extends beyond electrical specifications to encompass mechanical mounting, thermal management, and operational procedures. Components share common form factors, mounting systems, and management interfaces, reducing training requirements and simplifying spare parts inventory.

Key ecosystem benefits:

- Single-source accountability: One supplier responsible for entire power chain performance

- Pre-validated compatibility: Components tested together, eliminating integration risks

- Unified monitoring: Common management platforms across all infrastructure elements

- Streamlined procurement: Simplified vendor management and consolidated support

- Optimised coordination: Protection devices and control systems engineered to work together

UPS Systems: Foundation of Power Protection

Uninterruptible power supplies form the cornerstone of data center electrical infrastructure, providing clean, continuous power during utility disturbances whilst battery systems initialise generator startup.

Flagship High-Power Modular UPS

Keor FLEX represents Legrand's flagship modular UPS solution, delivering industry-leading 98.5% efficiency through Silicon Carbide technology. This high-power system scales from 100kW up to 1.2MW in a single frame using 100kW hot-swappable modules, with parallel configurations expandable to 4.8MW. The SiC-based architecture minimizes internal heat generation, reducing cooling requirements and improving overall facility energy efficiency for hyperscale and AI-driven data center deployments.

Comprehensive UPS Portfolio

Legrand's integrated UPS portfolio addresses requirements across the complete data center spectrum:

High-Power Solutions: Keor XPE (600kVA to 2.1MVA) and UPSaver (333kVA to 21MVA) provide scalable power protection for large installations with hot-scalable modules and transformer-free designs supporting megawatt-scale data halls whilst maintaining modular serviceability.

Modular Platforms: Keor MOD RI delivers 25-50kVA configurations for rack-independent applications with 96.8% efficiency. Trimod HE addresses 10-80kW requirements with N+X redundancy using individual single-phase modules.

Conventional UPS: Keor HPE provides three-phase protection from 60kW to 600kW with 3-Level IGBT technology. Keor DK offers single-phase solutions from 1kVA to 20kVA for smaller IT installations.

High-Efficiency Operation

Modern double-conversion UPS systems achieve remarkable efficiency through advanced power electronics. High-efficiency platforms deliver up to 98.5% efficiency in double conversion mode, with ECO mode operation reaching 99% efficiency in systems where available.

High efficiency reduces both energy consumption and heat generation. A 1MW UPS operating at 96% efficiency dissipates 40kW as heat, whilst 99% efficiency reduces waste heat to just 10kW - a 75% reduction in cooling load for this component alone.

Seamless Integration with Distribution

UPS systems connect directly to Legrand's distribution infrastructure through standardised interfaces. Output circuits integrate with static transfer switches for dual-path redundancy, switchgear for protection and isolation, and busway systems for flexible power distribution throughout the facility.

Internal DC buses within UPS systems provide natural integration points for DC distribution applications, battery energy storage, and renewable energy sources - supporting hybrid power architectures without additional conversion stages.

Static Transfer Switches: Dual-Path Redundancy

Static Transfer Switches (STS) provide automatic switching between independent AC power sources, ensuring continuous operation during source failures whilst preventing fault propagation between paths.

Legrand's STS range spans 16A to 3000A across single-phase and three-phase configurations. Solid-state Silicon Controlled Rectifiers (SCRs) enable seamless load transfer within quarter-cycle timeframes - typically 4 milliseconds - preventing disruption to connected equipment.

STS features ensuring reliability:

- Zero switching time: SCR-based transfer prevents momentary interruptions

- Source isolation: Prevents faults on one path affecting the alternate source

- Dual maintenance bypass: Enables STS servicing without load interruption

- Modular design: Thyristor protection fuses and isolation transformers field-replaceable

- Comprehensive monitoring: RS485 Modbus-RTU and optional SNMP interfaces

The rugged design withstands demanding data center environments whilst dual maintenance bypass paths permit complete STS replacement during operation. This architecture eliminates single points of failure in critical power paths.

Switchgear and Protection Devices

Switchgear controls power flow, isolates faults, and protects electrical infrastructure from overcurrent and short-circuit conditions. Proper protection device selection and coordination ensures faults clear at the lowest possible level without unnecessary upstream disconnection.

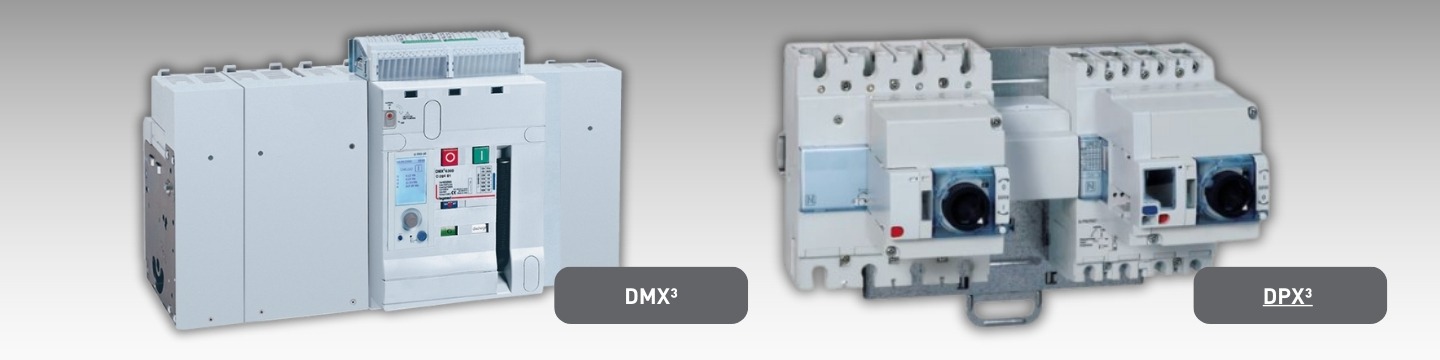

Air Circuit Breakers: DMX³ Series

DMX³ air circuit breakers protect main distribution boards with ratings from 630A to 6300A. Four breaking capacity options (42kA, 50kA, 65kA, 100kA) accommodate diverse fault current conditions across facility sizes.

Electronic protection units enable precise adjustment of current limits and time delays, ensuring total selectivity with downstream protection whilst responding appropriately to fault conditions. Fixed and draw-out versions provide installation flexibility, with draw-out designs enabling breaker replacement without disturbing connections.

MP6 digital protection units offer advanced functions including ground fault protection, programmable trip curves, and comprehensive metering. Communication options integrate with building management systems through Modbus and other standard protocols.

Moulded Case Circuit Breakers: DPX³ Series

DPX³ MCCBs provide reliable protection for branch circuits with ratings from 16A to 1600A and breaking capacities from 16kA to 100kA. Four frame sizes accommodate diverse application requirements from small branch circuits to substantial distribution feeders.

Electronic versions (40A-1600A) incorporate integrated measurement, enabling power monitoring without additional metering devices. Dynamic and logical selectivity features maximise service continuity by coordinating with upstream protection to clear faults at the most appropriate level.

Three and four-pole configurations support various grounding schemes. Thermal-magnetic versions offer economical protection where measurement isn't required, whilst electronic models provide precise adjustment and advanced features.

Protection Coordination

Proper coordination ensures protection devices operate selectively - downstream devices clear faults before upstream protection trips, maintaining power to unaffected circuits. Legrand's switchgear incorporates electronic protection units enabling dynamic coordination impossible with purely thermal-magnetic devices.

Digital communication between protection devices enables advanced coordination strategies. When downstream devices detect fault conditions, they communicate with upstream protection to inhibit tripping, allowing adequate time for downstream clearance before upstream backup protection operates.

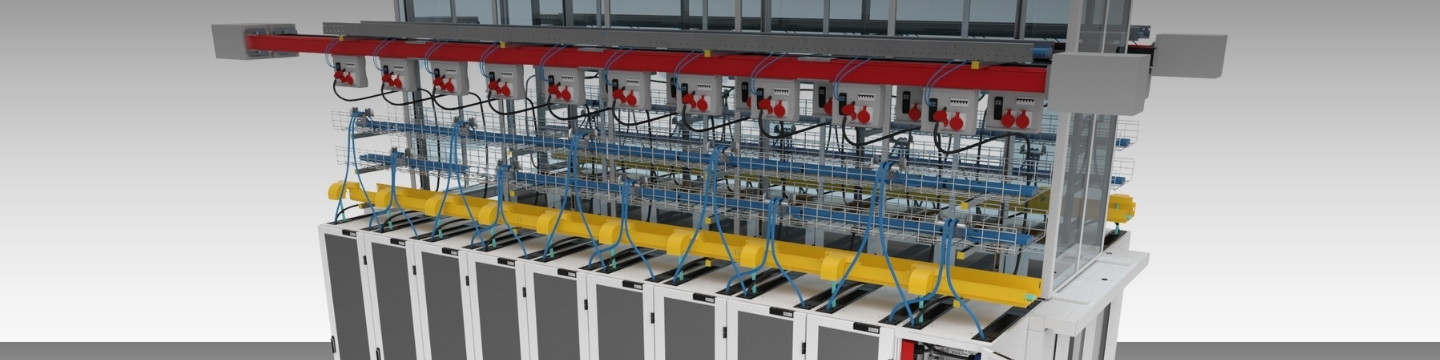

Busway Systems: Flexible Power Distribution

Overhead busway systems eliminate traditional conduit and cable installations, providing flexible tap-off points anywhere along distribution routes without requiring electricians to modify fixed wiring.

Starline Track Busway

Starline track busway revolutionised data center power distribution when introduced in 1987, establishing continuous bottom-access busbar systems as the industry standard for flexible power delivery.

The T5 series spans 250A to 1250A capacity with patented U-shaped copper busbars creating constant tension for reliable electrical connections. Open channel design permits plug-in unit installation anywhere along the track whilst the system remains energised - a critical capability for dynamic data center environments.

T5 specifications and certifications:

- Capacity range: 250A, 400A, 600A, 800A, 1000A, 1200-1250A

- Voltage ratings: 600V continuous duty (1200A system rated 480V)

- Standards compliance: UL 857, IEC 61439-6, ETL listed, CE marked

- Installation speed: Up to 90% faster than traditional conduit and cable

- Maintenance: Compression joints eliminate bolted connections and retorquing requirements

The T3 series addresses 100-225A applications where lower capacity suffices. Both series feature remote actuation capabilities enabling plug-in unit operation without exposing personnel to energised components - enhancing safety during maintenance activities.

Cable Busway Solutions

Legrand's cable busway offerings include two complementary systems addressing diverse project requirements. The Cablofil cable bus provides field-adjustable solutions for facilities requiring installation flexibility.

Power Bus Way (acquired 2024) delivers custom-designed cable bus systems for high-power applications reaching 6000A. This engineered, certified system utilises single conductor cables in free-air ventilated enclosures, designed to withstand short-circuit events whilst maintaining safe operating conditions.

Both systems support quick modifications without extensive rewiring - critical for data centers facing frequent layout changes as computing requirements evolve.

Power Distribution Units: Rack-Level Intelligence

PDUs distribute power from busway tap-offs or panel boards to individual equipment within racks, providing the final stage of power delivery plus comprehensive monitoring capabilities.

Intelligent PDU Platforms

Raritan PX4 and Server Technology PRO4X intelligent PDUs combine reliable power distribution with advanced metering, environmental monitoring, and remote control capabilities.

Intelligent PDU capabilities:

- Inlet metering: Comprehensive monitoring of total PDU power consumption

- Outlet-level measurement: Per-outlet current, voltage, power, and energy data

- Environmental sensing: Temperature, humidity, airflow, and other parameters via integrated sensors

- Remote outlet control: Individual outlet switching for equipment reboot and power sequencing

- Hot-swappable intelligence: Replaceable controller modules enabling upgrades without PDU replacement

The PRO4X achieves ±0.5% metering accuracy at inlet and outlet levels - 50% improvement over previous generations. Enhanced metrics including neutral voltage, total harmonic distortion, and voltage swell/dip detection enable comprehensive power quality monitoring.

HDOT Cx outlet technology combines C13 and C19 functionality in single outlets, accommodating either C14 or C20 plugs. This innovation reduces PDU complexity whilst improving flexibility as equipment changes.

Unified Management: Xerus Technology Platform

Both Raritan and Server Technology PDUs operate on the Xerus Technology Platform, providing consistent management interfaces across product families. Open APIs support SNMP, Modbus, REST, and Redfish protocols, ensuring compatibility with leading DCIM and BMS platforms.

Hot-swappable iX controllers enable firmware updates, feature enhancements, and hardware improvements without replacing entire PDUs. Multi-PDU power sharing maintains monitoring during input feed failures by sharing controller power between adjacent units.

High Power Busbar Systems

Purpose-engineered busbars distribute power at the grey space level, connecting utility services to rack-row distribution with minimal conversion losses.

Legrand's high-power busbar range includes the XCP series delivering 630A to 6300A capacity with IP68 environmental protection. RCP and XCP-HP variants address different installation requirements whilst maintaining consistent interface standards.

UL certification and real-time temperature sensing ensure safe operation under full load conditions. Modular tap-off units provide connection points for downstream distribution without interrupting the primary busbar, supporting phased installation and future expansion.

Electrical Safety Standards and Certifications

Comprehensive safety certification ensures Legrand's electrical ecosystem meets or exceeds requirements across global markets, protecting both personnel and equipment whilst simplifying regulatory compliance.

International Standards Compliance

Legrand products maintain rigorous compliance with international safety standards:

IEC standards compliance:

- IEC 61439-6: Busbar trunking systems

- IEC 62040: Uninterruptible power systems (UPS)

- IEC 62368-1: Audio/video, information and communication technology equipment

- IEC 60947: Low-voltage switchgear and control gear

North American certifications:

- UL 857: Busways

- UL 2755: Modular data centers (system-level certification)

- UL listing: Comprehensive product line listing ensuring NEC compliance

- ETL certification: Third-party verification of safety standards

Regional certifications:

- CE marking: European conformity enabling EU market access

- CCC certification: China Compulsory Certificate for Chinese market

- VDE certification: German safety standards verification

Quality and Information Security

Beyond product safety, Legrand maintains comprehensive quality and cybersecurity certifications addressing modern data center requirements.

ISO/IEC 27001:2013 certification for the Data, Power & Control division demonstrates highest-standard information security management across R&D facilities in Somerset NJ, Reno NV, Canonsburg PA, and Zwickau Germany. This certification encompasses all 114 required process controls plus additional vulnerability and penetration testing for network-connected products.

ISO 9001 quality management and ISO 14001 environmental management certifications ensure consistent product quality whilst minimising environmental impact throughout product lifecycles. ISO 9001:2015 certification by Intertek for Power Bus Way facilities demonstrates manufacturing quality across the expanded portfolio.

Installation Best Practices

Proper installation procedures ensure electrical systems operate safely and reliably throughout their service lives. Legrand supports installers through comprehensive documentation, training programmes, and field support services.

Grounding and Bonding

Effective grounding systems protect personnel and equipment by providing low-impedance paths for fault currents. All conductive components must bond together and connect to facility ground, ensuring protective devices operate correctly during fault conditions.

Legrand's wire mesh cable trays utilise UL-classified splices meeting NEMA VE1, NEC, and UL resistance requirements. Proper splice installation maintains electrical continuity throughout cable management systems, whether serving as Equipment Grounding Conductor (EGC) or supplemented by separate grounding conductors.

Busway systems incorporate continuous grounding throughout enclosures and plug-in units, providing reliable fault current paths without requiring separate grounding conductors at tap-off points.

Protection Coordination Studies

Coordination studies ensure protection devices operate selectively during fault conditions. Engineers analyse fault current magnitudes at various points throughout the distribution system, then select device ratings and settings ensuring proper coordination.

Legrand's digital protection units simplify coordination through precise adjustment of trip curves and communication-based coordination strategies. Software tools assist engineers in evaluating coordination across complex distribution networks incorporating multiple protection levels.

Thermal Management

Electrical equipment generates heat proportional to losses. Proper spacing, ventilation, and thermal management prevent excessive temperatures that degrade insulation and reduce equipment life.

Busway systems dissipate heat through ventilated enclosures enabling free-air cooling. UPS systems incorporate intelligent fan control adjusting cooling based on load and component temperatures rather than operating continuously at maximum speed. PDUs locate controllers away from high-current connections, preventing heat from metering circuits affecting electronic components.

Optimised System Uptime Through Integration

The true value of Legrand's integrated ecosystem emerges during normal operations and emergency scenarios when components must work together flawlessly.

Redundancy Architecture Support

Data center redundancy requires coordinated operation across multiple power paths. Legrand's ecosystem supports 2N, N+1, and distributed redundancy architectures through products designed for parallel operation and automatic failover.

Modular UPS systems parallel internally and externally, providing scalable redundancy from module level to system level. Static transfer switches integrate with dual-path distribution, automatically selecting the optimal source without operator intervention. PDUs support dual-input configurations with automatic source selection ensuring continuous rack power during source transitions.

Predictive Maintenance Capabilities

Intelligent monitoring enables predictive maintenance strategies identifying potential failures before they cause downtime. Comprehensive data from PDUs, UPS systems, and protection devices feeds analytics platforms detecting trends indicating degrading components.

Temperature monitoring in busway systems detects hot spots suggesting loose connections or overloaded circuits. UPS battery monitoring tracks capacity degradation, predicting replacement requirements before runtime falls below required thresholds. Protection device diagnostics identify operation outside normal parameters, prompting investigation before failures occur.

Simplified Troubleshooting

Unified monitoring platforms and consistent interfaces across the ecosystem accelerate troubleshooting during fault conditions. Rather than navigating disparate management systems with different interfaces and protocols, operators access comprehensive status through single platforms.

Common LED status indicators and display formats reduce training requirements and minimise response time during emergencies. Maintenance personnel familiar with one Legrand product line rapidly adapt to other ecosystem components sharing common design philosophies.

Conclusion

Mission-critical data centers require electrical infrastructure delivering uncompromising reliability whilst accommodating growth and change. Fragmented component selection creates integration challenges that compromise both uptime and safety.

Legrand's integrated electrical ecosystem provides pre-engineered compatibility across UPS systems, static transfer switches, switchgear, busway distribution, and rack PDUs. Comprehensive safety certifications spanning UL, IEC, and regional standards ensure regulatory compliance whilst protecting personnel and equipment.

This cohesive approach simplifies procurement, accelerates installation, and optimises ongoing operations through unified monitoring and predictive maintenance capabilities. By selecting ecosystem components engineered to work together, data center operators reduce integration risks whilst positioning infrastructure to support evolving requirements over decades of service life.

The ecosystem delivers not just individual components, but complete solutions addressing the full scope of data center electrical distribution - from utility interconnection through rack-level power delivery, all backed by single-source accountability ensuring safe, reliable operation of mission-critical infrastructure. Contact our data center expert now.

Canada

Canada

Latin America (English)

Latin America (English)

Latin America (Espanol)

Latin America (Espanol)

USA

USA

China

China

India

India

Japan

Japan

Republic of Korea

Republic of Korea

South East Asia (English)

South East Asia (English)

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Netherlands

Netherlands

Spain

Spain

Switzerland

Switzerland

Turkey

Turkey

UK

UK

Africa (english)

Africa (english)

Africa (français)

Africa (français)

Middle East (english)

Middle East (english)

Australia

Australia

New Zealand

New Zealand