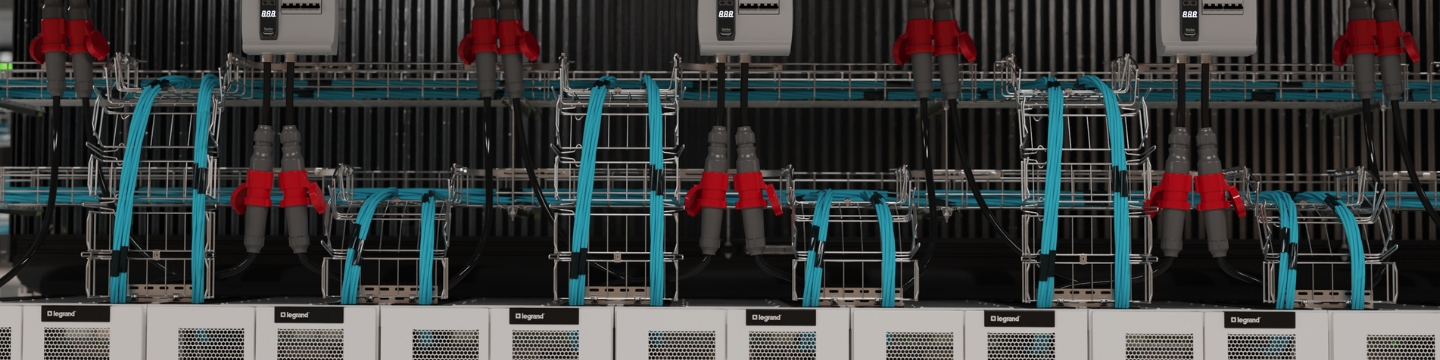

Best Practices for UPS Installation, Commissioning, and Maintenance in Data Centers

Uninterruptible power supply systems protect mission-critical infrastructure, but their reliability depends entirely on proper installation, thorough commissioning, and disciplined maintenance protocols. Inadequate installation practices compromise safety and performance from day one. Rushed commissioning misses critical configuration errors that manifest during emergencies. Deferred maintenance allows minor issues to escalate into catastrophic failures precisely when backup power is needed most.

Legrand's technical expertise across decades of UPS deployments has identified the practices that separate reliable installations from problematic ones. This guide presents field-proven approaches to UPS system design planning, integration procedures, environmental considerations, and maintenance protocols that maximise reliability and operational efficiency in demanding data center environments.

System Design Planning

Successful UPS installations begin long before equipment arrives on-site. Comprehensive planning addresses electrical requirements, space constraints, future growth, and integration with existing infrastructure.

Load Assessment and Capacity Planning

Accurate load assessment forms the foundation of proper UPS sizing. Begin by cataloguing all protected equipment with nameplate ratings, startup current requirements, and power factors. Many devices specify VA ratings whilst actual power consumption measures in watts - UPS capacity must accommodate both.

Critical load assessment steps:

- Document all protected equipment with VA/watt ratings and power factors

- Measure actual power consumption where possible - nameplate ratings often overstate requirements

- Calculate total load including startup inrush current for equipment with motors or transformers

- Add 20-30% capacity margin for future growth without oversizing excessively

- Separate truly critical loads requiring continuous backup from equipment suitable for controlled shutdown

Legrand's modular UPS platforms support right-sizing strategies. The Keor FLEX delivers scalable capacity from 100 kW modules up to 1.2 MW in a single frame, with parallel configurations reaching 4.8 MW for hyperscale deployments. This modular approach optimises both capital expenditure and operational efficiency by allowing incremental capacity additions as requirements grow.

Runtime Requirements

Battery runtime specifications vary dramatically across applications. Edge computing sites may require extended runtime awaiting generator startup or utility restoration. Core data centers typically need only 5-15 minutes - sufficient for generator synchronisation and controlled load transfer.

Runtime calculations must account for battery ageing. New batteries deliver nameplate capacity, but performance degrades over service life. Size battery strings to provide required runtime at 80% capacity - the typical replacement threshold - ensuring adequate backup throughout the battery lifecycle.

Temperature significantly affects battery performance. Capacity calculations assume 25°C (77°F) ambient temperature. Higher temperatures reduce available capacity whilst lower temperatures slow charge acceptance. Factor temperature correction when operating outside this range.

Space and Environmental Planning

UPS systems require adequate clearance for ventilation, service access, and future expansion. Legrand installation manuals specify minimum clearances that vary by model and configuration. Consult specific product documentation for exact clearance requirements, as these differ across UPS families based on their design and service needs.

Space planning considerations:

- Service clearance for hot-swappable module replacement and battery drawer access

- Cable entry routes supporting recommended bend radii without strain on terminations

- Battery cabinet placement considering weight distribution and structural loading

- Future expansion space for additional UPS modules or parallel units

- Environmental control ensuring 0-40°C (32-104°F) operating temperature range

Inadequate ventilation creates hotspots that accelerate component ageing. Battery life halves for every 8-10°C above 25°C. Cooling systems must maintain stable temperatures, not just prevent overheating during peak loads.

Electrical Integration and Circuit Protection

UPS systems integrate into facility electrical distribution requiring careful attention to protection coordination, grounding, and cable sizing.

Input Circuit Protection

Input circuit breakers must coordinate with UPS rectifier ratings while providing adequate fault protection. Manufacturer technical documentation specifies recommended protection devices based on UPS capacity, rectifier topology, and input configuration.

For systems with combined bypass and rectifier inputs, total input protection must reflect the combined load and worst-case operating conditions. Systems with separate bypass and rectifier inputs allow independent protection optimized for each function, improving selectivity, maintainability, and service flexibility.

Input protection requirements:

- Circuit breakers, typically equipped with electronic trip units for medium and large UPS systems, rated for total input current and adjustable to accommodate rectifier inrush currents and harmonic effects

- Breaking capacity adequate for the available short-circuit current at the installation point

- Selectivity with upstream distribution to ensure faults are cleared at the appropriate protection level

- Residual current protection, where required by local regulations, must be selected according to the earthing system and UPS rectifier topology; Type B RCDs (typically ≥300 mA, time-delayed) may be required on UPS inputs where DC leakage currents are possible, subject to manufacturer approval and national wiring rules.

Legrand's DMX³ and DPX³ switchgear provide precisely adjustable protection coordinating with UPS specifications. Switchgear with electronic protection units enables precise adjustment of long-time, short-time, and instantaneous settings, supporting effective coordination with UPS operating characteristics and discrimination throughout the distribution network.

Output Circuit Protection and Distribution

UPS output protection must discriminate with downstream distribution while responding appropriately to the inverter’s limited short-circuit current capability. Battery-backed inverters typically deliver fault currents of approximately 2–3 times rated current, significantly lower than utility-supplied sources.

Protection devices must be verified to operate reliably at these reduced fault levels while avoiding nuisance tripping during normal load transients. Coordination studies must confirm correct discrimination in both inverter mode and bypass mode, the latter representing the worst-case fault condition due to higher available short-circuit current.

Cable sizing for UPS outputs follows standard calculation methods but must consider continuous full-load operation, termination temperature ratings, harmonic current effects, and potential neutral conductor overloading. Unlike utility-supplied circuits, UPS output conductors are designed to carry rated current continuously during normal operation.

Grounding and Bonding

Proper grounding protects personnel and equipment while ensuring protective devices operate correctly during fault conditions. All exposed conductive parts of the UPS must be bonded to the facility protective earth (PE) system in accordance with applicable standards and local electrical codes.

Legrand UPS systems are equipped with dedicated grounding terminals designed to accept protective conductors sized per national regulations. Grounding conductors must present a low-impedance path throughout their length, as loose connections, excessive length, or degraded terminations can impair fault clearance and compromise safety.

In parallel UPS configurations, grounding and bonding arrangements require particular attention to prevent unintended circulating currents and electromagnetic interference. Grounding schemes should be based on a clearly defined common reference point within the installation, ensuring equipotential bonding while avoiding multiple parallel earth paths that could lead to unpredictable current flow.

Installation Best Practices

Proper installation procedures ensure UPS systems operate safely and reliably from initial commissioning throughout their service lives.

Receiving and Storage

UPS equipment requires careful handling to prevent damage before installation. Legrand manuals specify transportation and storage requirements that must be followed to maintain warranty coverage.

Equipment handling protocols:

- Inspect packaging for shipping damage - photograph any issues before accepting delivery

- Verify equipment matches delivery documentation and purchase orders

- Check shock indicators on packaging - report any exceeded thresholds immediately

- Store equipment in climate-controlled environments within 0-40°C range

- Maintain vertical orientation during storage and transportation

- Recharge batteries within 24 hours if storage exceeds 6 months to prevent deep discharge

Deep battery discharge voids warranties and permanently damages cells. Equipment in extended storage requires periodic charging per manufacturer specifications.

Mechanical Installation

UPS cabinets must stand on level, load-bearing surfaces capable of supporting total weight including batteries. Legrand modular systems specify floor loading per square metre - verify structural adequacy before positioning equipment.

Seismic considerations require anchoring in regions subject to earthquakes. Mounting kits secure cabinets to floors preventing movement during seismic events. Flexible conduit connections between adjacent cabinets accommodate relative motion without breaking conductors.

Battery cabinets positioned separately from UPS electronics require secure interconnections supporting battery cable weight whilst permitting thermal expansion. Rigid conduit installations can stress terminations as materials expand with temperature variations.

Electrical Connections

All electrical terminations require proper torque application per manufacturer specifications. Under-torqued connections develop high resistance causing heat generation and voltage drop. Over-torqued terminations damage conductors and terminals, compromising mechanical and electrical integrity.

Connection procedure requirements:

- Clean all termination surfaces removing oxidation or contamination

- Apply anti-oxidation compound on aluminium conductors

- Torque all terminations using calibrated tools to specified values

- Mark torqued connections with paint or marker indicating completed work

- Verify termination tightness after 24 hours of energisation - thermal cycling can loosen connections

- Document all termination torque values in commissioning records

Legrand technical documentation specifies torque values for all terminations. Larger systems provide multiple connection points per phase - current must distribute evenly across parallel conductors to prevent imbalanced heating.

Commissioning Procedures

Thorough commissioning validates correct installation, verifies all protection and control functions, and establishes baseline performance data for future comparison.

Pre-Energisation Checks

Before applying power, comprehensive inspections verify installation completeness and correctness. These checks prevent equipment damage and safety hazards during initial energisation.

Pre-energisation verification:

- Visual inspection of all electrical connections for tightness and correct routing

- Verification of circuit breaker settings matching design specifications

- Continuity testing of grounding conductors throughout system

- Insulation resistance testing confirming no faults to ground

- Battery string polarity verification preventing reversed connections

- Control circuit wiring verification per wiring diagrams

- Confirmation of proper battery fuse installation and ratings

Legrand UPS systems include diagnostic routines detecting many configuration errors, but proper pre-energisation checks catch issues before they damage equipment or create safety hazards.

Functional Testing

Systematic functional testing validates all UPS operating modes and protection functions under controlled conditions. Legrand service engineers supervise commissioning for larger systems, ensuring thorough testing and proper configuration.

Commissioning test sequence:

- Rectifier operation: Verify input voltage within limits, rectifier synchronises with input, DC bus reaches specified voltage

- Battery charging: Confirm charge current at expected level, battery voltage rises appropriately, no excessive heating

- Inverter operation: Validate output voltage regulation, frequency stability, phase balance across all three phases

- Load transfer testing: Verify seamless transfer between normal, bypass, and battery modes without disruption

- Parallel operation (if applicable): Confirm load sharing accuracy, communication between units, redundancy loss alarms

- Protection functions: Test input undervoltage transfer, output overload response, battery low voltage shutdown

- Battery discharge test: Measure actual runtime under representative load confirming capacity specifications

Test documentation includes all measured parameters compared against specifications. Deviations require investigation and resolution before final acceptance.

Site Acceptance Testing

Site acceptance tests demonstrate UPS performance meeting design requirements under actual operating conditions. These tests often occur after protected loads connect but before declaring the system operational for critical applications.

Load bank testing validates UPS capacity and battery runtime under full rated load. This comprehensive test stresses all components revealing any installation defects or configuration errors before placing the system into service protecting critical loads.

Site acceptance deliverables:

- Complete test results documenting all measured parameters

- Comparison of performance against specifications

- As-built drawings reflecting any field modifications

- Configuration files backup for UPS control systems

- Operator training completion certificates

- Spare parts inventory list

- Warranty registration documentation

Legrand provides comprehensive test and commissioning reports detailing all procedures performed and results achieved, establishing baseline performance documentation for the installation lifecycle.

Environmental Considerations

Environmental conditions profoundly impact UPS reliability and battery life. Proper environmental control extends equipment life and ensures availability during emergencies.

Temperature Management

UPS electronics operate reliably across 0-40°C ranges, but batteries are far more sensitive. Optimal battery life occurs at 20-25°C. Every 8-10°C above this range halves battery lifespan.

A battery designed for 5-year life at 25°C may last only 2.5 years at 35°C. Data centers running warm to improve cooling efficiency must balance energy savings against accelerated battery replacement costs and reduced reliability.

Temperature control strategies:

- Dedicated cooling for battery rooms separate from general facility HVAC

- Temperature monitoring throughout battery strings identifying hot spots

- Airflow management preventing recirculation of warm exhaust air

- Thermal insulation between battery cabinets and heat-generating electronics

- Setpoint alarms triggering before temperatures reach damaging levels

Modern UPS systems incorporate temperature sensors throughout battery strings. Monitoring these sensors identifies developing thermal issues before they cause failures.

Humidity Control

Relative humidity should remain between 20-80% non-condensing. High humidity promotes corrosion at electrical connections whilst low humidity increases static electricity risks to sensitive electronics.

Condensation poses particular danger during temperature transitions. Battery rooms warming after extended cool periods can develop condensation on cold surfaces. Gradual temperature changes and adequate air circulation prevent condensation formation.

Contamination Prevention

Airborne contaminants including dust, metal particles, and chemical vapours degrade UPS components over time. Conductive dust settling on circuit boards can cause tracking between conductors. Corrosive chemical vapours attack connections and electronic components.

Data center air filtration systems should maintain positive pressure preventing contaminated outside air from infiltrating equipment spaces. Regular cleaning removes accumulated dust before it causes problems. Battery terminals particularly require inspection and cleaning as corrosion at these high-current connections generates heat and voltage drop.

Maintenance Protocols

Disciplined preventive maintenance identifies developing issues before they cause failures, maximises equipment life, and ensures readiness when backup power is required.

Routine Inspection Schedule

Regular inspections detect problems early when correction is straightforward and inexpensive. Deferred maintenance allows minor issues to compound into major failures requiring emergency intervention.

Monthly inspection tasks:

- Visual inspection of all indicator lights and display messages

- Battery voltage verification across all strings

- Environmental condition check (temperature, humidity, cleanliness)

- Connection point visual inspection for overheating or corrosion

- Event log review identifying any alarms or unusual operation

- Battery room walkthrough checking for leaks, swelling, or damage

Quarterly inspection tasks:

- Detailed battery inspection including individual cell voltages

- Torque verification on critical electrical connections

- Cooling system filter inspection and replacement as needed

- UPS self-test initiation validating battery discharge capability

- Firmware and configuration file backup

- Documentation review ensuring procedures remain current

Annual inspection tasks:

- Comprehensive load testing validating capacity and runtime

- Battery impedance or conductance measurements

- Thermal imaging of all electrical connections and components

- Detailed protection coordination verification

- Parallel system operation testing (if applicable)

- Training review and updates for operations personnel

Legrand provides detailed maintenance schedules in system documentation. Following these schedules maintains warranty coverage and optimises system reliability.

Battery Maintenance and Technology Options

Batteries represent the most failure-prone UPS component whilst being absolutely critical to backup operation. Comprehensive battery maintenance prevents the majority of UPS-related downtime.

Legrand UPS systems support multiple battery technologies including VRLA (Valve Regulated Lead Acid) and lithium-ion batteries, each with distinct characteristics. VRLA batteries remain widely deployed due to their proven reliability and cost-effectiveness, whilst lithium-ion offers longer service life and higher power density for applications where these benefits justify the higher initial investment.

Battery maintenance essentials:

- Float voltage monitoring across all battery strings and individual cells

- Temperature measurement identifying thermal issues

- Visual inspection for physical damage, leaks, swelling, or corrosion

- Connection torque verification annually or after any battery work

- Impedance or conductance testing detecting cells approaching end-of-life

- Load testing validating actual capacity against requirements

Battery replacement intervals depend on several factors including battery chemistry, operating temperature, discharge cycles, and maintenance quality. Consult specific battery manufacturer recommendations and UPS installation manuals for guidance on expected service life and replacement criteria for your installation's battery type and operating conditions.

Capacity testing applies realistic discharge loads measuring actual runtime. Compare results against baseline data from commissioning. Replace batteries when capacity drops below 80% of rated specifications - continuing operation below this threshold risks inadequate runtime during emergencies.

Preventive Replacement

Proactive battery replacement before failure prevents emergency situations. Battery monitoring trends guide replacement decisions. Gradual voltage decline, increasing impedance, and reduced capacity indicate approaching end-of-life. Scheduled replacement during planned maintenance windows costs far less than emergency replacement after failure.

Document all battery replacements including date, manufacturer, model, battery chemistry, and baseline test results. This data enables lifecycle analysis and replacement planning for subsequent battery generations.

Training and Documentation

Even perfectly installed and maintained UPS systems fail if operators don't understand proper procedures or documentation is unavailable during emergencies.

Operator Training Requirements

Comprehensive operator training ensures personnel can monitor UPS status, respond appropriately to alarms, and perform basic troubleshooting without creating additional problems.

Essential operator training topics:

- UPS operating modes and automatic transitions

- Control panel interpretation including status indicators and alarm messages

- Routine monitoring procedures and normal parameter ranges

- Proper procedures for bypass operation during maintenance

- Emergency shutdown procedures and when to execute them

- Load management during extended utility outages

- Battery discharge testing protocols

- When to contact technical support versus handling locally

Legrand provides operator training as part of commissioning services. Annual refresher training maintains competency as staff changes and system configurations evolve.

Documentation Management

Comprehensive documentation enables effective troubleshooting, informs maintenance decisions, and ensures critical information is available when needed.

Required documentation:

- Complete electrical single-line diagrams showing UPS interconnections

- As-built drawings reflecting field modifications from design

- Manufacturer's installation and operation manuals

- Protection coordination study results

- Commissioning test reports establishing baseline performance

- Battery installation date, chemistry type, and baseline capacity test results

- Maintenance log recording all inspection findings and corrective actions

- Configuration file backups for UPS control systems

Store documentation both at the installation site and off-site protecting against loss during facility emergencies. Digital copies in multiple secure locations ensure availability when needed.

Maximising UPS Performance

Beyond basic installation and maintenance, several practices optimise UPS performance throughout the system lifecycle.

Configuration Optimisation

UPS systems incorporate numerous adjustable parameters controlling operation under various conditions. Default settings suit general applications but specific installations benefit from optimisation.

Battery charge rates affect battery life and recharge time after discharge. Higher charge rates restore capacity quickly but generate heat and stress batteries. Lower rates extend battery life but prolong vulnerability after utility restoration. Optimal settings balance these competing requirements based on site-specific conditions and battery chemistry.

Bypass voltage and frequency tolerances determine when UPS transfers loads to bypass versus continuing inverter operation. Tight tolerances maximise power conditioning but may cause unnecessary transfers in areas with marginal utility quality. Site-specific adjustment optimises for local conditions.

Parallel System Considerations

Parallel UPS installations provide redundancy and additional capacity but require careful configuration ensuring proper load sharing and protection coordination.

Load sharing accuracy affects reliability. Imbalanced loading concentrates stress on heavily loaded units whilst underutilising others. Modern systems achieve 1-2% load sharing accuracy, but achieving this requires proper installation and configuration.

Communication between parallel units coordinates transfer operations and provides redundancy monitoring. Verify communication integrity regularly - loss of communication between units can compromise coordination during emergencies.

Continuous Improvement

Regular performance review identifies optimisation opportunities and emerging issues before they compromise availability.

Trend analysis of battery parameters predicts replacement requirements enabling planned interventions. Gradual voltage decline over months indicates approaching end-of-life, whilst sudden changes suggest developing faults requiring immediate attention.

Event log analysis reveals patterns indicating environmental issues, electrical disturbances, or configuration problems. Frequent bypass transfers may indicate input power quality problems requiring utility investigation. Repeated battery low voltage alarms suggest capacity degradation or excessive load.

Conclusion

UPS reliability depends equally on proper installation, thorough commissioning, and disciplined maintenance. Shortcuts during installation create problems that persist throughout system life. Inadequate commissioning misses configuration errors that compromise emergency operation. Deferred maintenance allows minor issues to escalate into major failures.

Legrand's technical expertise and comprehensive documentation support best-practice implementation across all UPS system phases. Following manufacturer guidelines, maintaining environmental controls, and executing disciplined preventive maintenance maximises reliability whilst optimising operational efficiency.

Data center operators implementing these practices protect critical infrastructure whilst minimising lifecycle costs through extended equipment life and reduced emergency interventions. The investment in proper procedures pays continuous dividends through reliable operation when backup power is needed most. Contact us for more informations.

Canada

Canada

Latin America (English)

Latin America (English)

Latin America (Espanol)

Latin America (Espanol)

USA

USA

China

China

India

India

Japan

Japan

Republic of Korea

Republic of Korea

South East Asia (English)

South East Asia (English)

Austria

Austria

Belgium

Belgium

France

France

Germany

Germany

Italy

Italy

Netherlands

Netherlands

Spain

Spain

Switzerland

Switzerland

Turkey

Turkey

UK

UK

Africa (english)

Africa (english)

Africa (français)

Africa (français)

Middle East (english)

Middle East (english)

Australia

Australia

New Zealand

New Zealand